5 Compelling Benefits of Choosing Vacuum Lifting Equipment for Your Business

In the fast-evolving landscape of industrial operations, the adoption of innovative handling technologies has become imperative for businesses seeking efficiency and safety. One such technology that is gaining traction is Vacuum Lifting Equipment, a solution that significantly enhances material handling processes across various sectors. According to a report by Grand View Research, the global vacuum lifting equipment market is projected to reach USD 1.2 billion by 2025, with a compound annual growth rate (CAGR) of 5.8%. This growth is attributed to the increasing demand for automated solutions that not only streamline operations but also reduce the risk of workplace injuries associated with manual handling.

Furthermore, the use of Vacuum Lifting Equipment is aligned with modern workplace safety regulations and trends emphasizing the importance of ergonomics. A survey conducted by the Occupational Safety and Health Administration (OSHA) found that lifting-related injuries account for about 20% of all workplace injuries in the manufacturing and construction sectors. By incorporating vacuum lifting technology, companies can significantly mitigate these risks while optimizing performance. This blog will explore five compelling benefits of choosing Vacuum Lifting Equipment for your business, detailing how it can transform operations and contribute to a safer work environment.

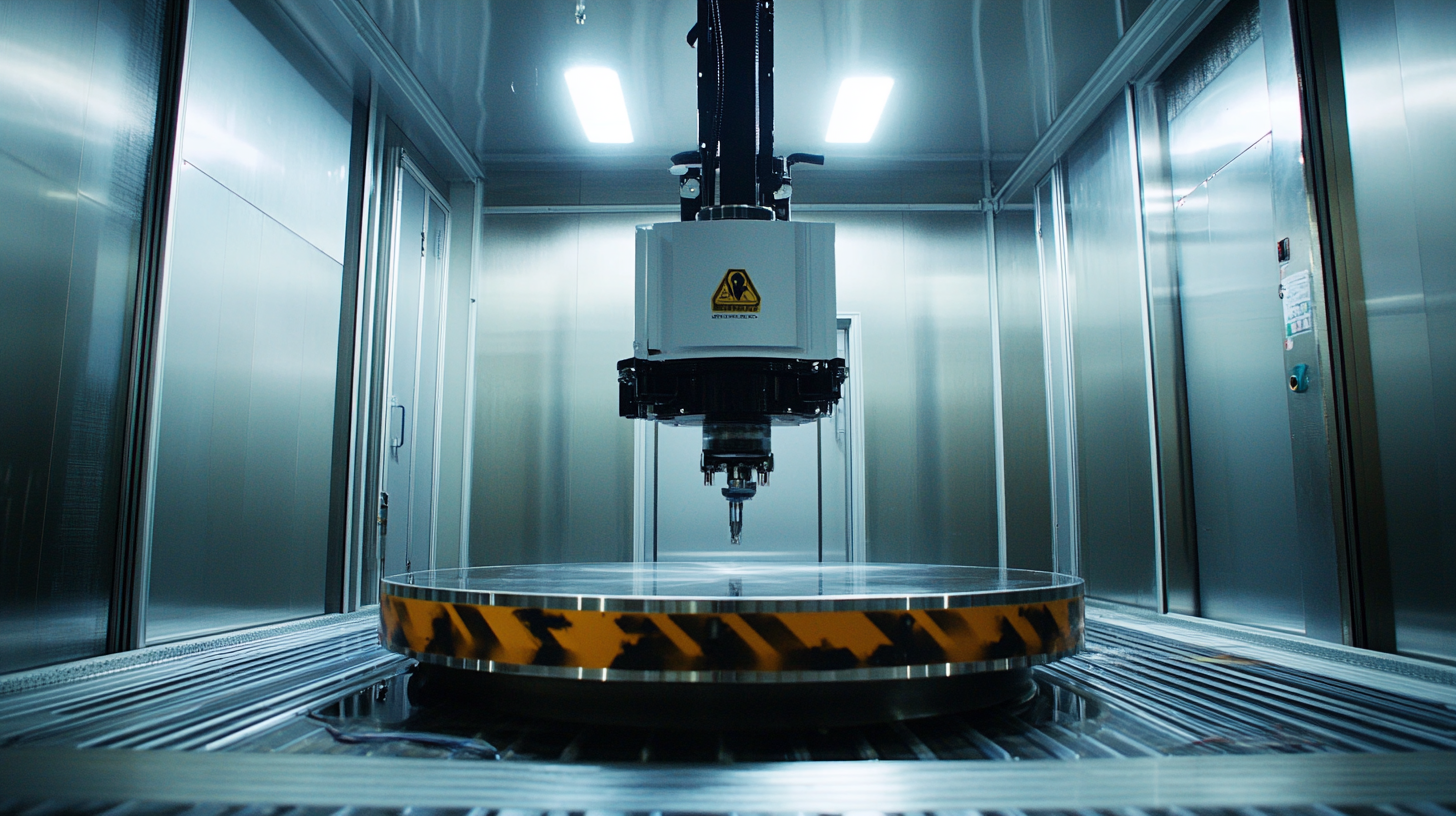

Understanding the Efficiency of Vacuum Lifting in Material Handling

When it comes to material handling, efficiency is key to improving productivity and reducing operational costs. Vacuum lifting equipment has emerged as a game-changer for various industries, offering a streamlined solution to manage heavy and cumbersome loads. The technology operates on a simple principle: it uses suction to lift items securely and move them with precision. This innovative approach not only enhances safety for workers but also speeds up the handling process significantly. One of the most compelling advantages of vacuum lifting is its adaptability to various materials and shapes. Whether dealing with pallets, sheets of glass, or irregularly shaped items, vacuum lifters can handle diverse loads with ease. This versatility minimizes the need for multiple handling systems, allowing businesses to optimize their equipment investments. Additionally, the gentle touch of vacuum lifting reduces the risk of damage to sensitive materials, leading to lower costs and fewer product losses. Moreover, the ergonomic benefits of vacuum lifting equipment cannot be overlooked. By reducing the physical strain on workers, businesses can improve employee satisfaction and decrease the likelihood of workplace injuries. This not only leads to a healthier workforce but also translates into lower insurance costs and enhanced productivity. Ultimately, the efficiency of vacuum lifting in material handling is a vital element that can drive operational success in any business setting.

Reducing Workplace Injuries Through Vacuum Lifting Solutions

As workplace injuries continue to rise, particularly in sectors like baggage handling, the need for effective lifting solutions has never been more urgent. Vacuum lifting equipment has emerged as a practical response to this pressing issue, leveraging advanced suction technology to minimize the physical strain placed on workers. By securely gripping heavy packages, these devices allow employees to move items effortlessly, significantly reducing the likelihood of back injuries and other musculoskeletal disorders.

Research indicates that the implementation of vacuum lifting systems can lead to impressive safety outcomes. For instance, studies have shown a notable decrease in compression and shear forces on the lower back, with reductions of up to 39% and 25%, respectively. Such statistics highlight the ability of vacuum lifting devices to alleviate the physical demands of lifting and transporting heavy loads, providing a safer work environment.

In addition to enhancing safety, vacuum lifting solutions contribute to overall workplace efficiency. By streamlining the process of handling goods, businesses can not only protect their employees but also improve productivity. As industries grapple with the dual challenges of rising injury rates and operational demands, investing in vacuum lifting equipment represents a proactive strategy for safeguarding both workers and organizational performance.

Enhancing Productivity: How Vacuum Lifting Speeds Up Operations

In today's fast-paced industrial environment, enhancing productivity is a constant goal for businesses of all sizes. One innovative solution that has gained traction is vacuum lifting equipment. By using this technology, companies can significantly speed up their operations, creating a more efficient workflow and reducing labor costs. The mechanics of vacuum lifting allow for quick and safe handling of heavy or bulky materials, which can dramatically minimize time spent on manual lifting and repositioning.

The speed at which vacuum lifting systems can operate is a game changer. Traditional methods often require multiple workers to safely move large items, leading to delays and increased risk of injury. In contrast, vacuum lifters can be operated by a single operator, who can efficiently move items with precision. This not only cuts down on the manpower needed for certain tasks but also frees up staff to focus on more value-added activities. As a result, operations become streamlined, allowing businesses to fulfill orders faster and improve overall throughput.

Moreover, the reliability of vacuum lifting technology contributes to enhanced productivity. These systems are designed for continuous use and are less prone to downtime compared to conventional lifting methods. With fewer breakdowns and maintenance issues, companies can maintain a steady pace of production, further reinforcing their competitive edge in the market. By investing in vacuum lifting equipment, businesses are not only modernizing their operations but also setting themselves up for long-term success through improved efficiency and productivity.

Cost-Effectiveness of Investing in Vacuum Lifting Equipment

Investing in vacuum lifting equipment can offer significant cost-effectiveness for businesses, particularly in industries facing challenges in efficiency and precision. As highlighted by recent industry reports, the global powder processing sector has seen a steady growth rate of approximately 8-12% annually, driven by rising demand for advanced handling technologies. In this context, vacuum lifting equipment stands out as a transformative solution, enhancing operational productivity while reducing labor costs and minimizing material waste.

Vacuum lifting systems not only streamline the lifting and transportation of heavy goods but also contribute to a safer working environment. The traditional powder processing methods often struggle with issues related to handling speed and accuracy, leading to higher operational costs. By adopting modern vacuum lifting technology, companies can mitigate these challenges, resulting in faster processing times and improved product quality. According to data from industry analysis, organizations that transitioned to vacuum systems reported up to a 30% reduction in handling costs, showcasing the practical savings tied to this investment.

Moreover, the medical suction device market is experiencing parallel growth, underscoring the expanding utility of vacuum technology across various sectors. As efficiency becomes paramount in both powder handling and medical applications, the cost-effectiveness of vacuum lifting equipment emerges as a strategic advantage. Embracing this technology not only enhances business operations but also positions companies to compete more effectively in an increasingly demanding marketplace.

Versatility of Vacuum Lifting: Applications Across Different Industries

Vacuum lifting equipment has gained significant traction across various industries due to its versatility and efficiency. From construction sites to manufacturing facilities, the ability to manipulate heavy loads with minimal manual handling is revolutionizing operations. According to a study conducted by the International Journal of Industrial Ergonomics, the use of vacuum lifting systems reduces the risk of workplace injuries by up to 50%, highlighting their importance across sectors where heavy lifting is commonplace.

In the logistics and warehousing sector, vacuum lifters streamline the process of moving bulky items, such as glass panels or steel sheets. They enable workers to handle materials more safely and efficiently, ultimately decreasing the time needed for loading and unloading. A market analysis published by MarketsandMarkets indicates that the global vacuum lifting equipment market is projected to grow from $2.3 billion in 2022 to $4.1 billion by 2027, with applications across diverse fields such as automotive, aerospace, and manufacturing.

Additionally, the food and packaging industry benefits from vacuum lifting technology, which facilitates the handling of fragile items like packaging and boxes. The hygienic design of many vacuum lifting solutions ensures compliance with health regulations, which is critical in sectors dealing with consumable goods. As industries continue to prioritize safety and efficiency, the adoption of vacuum lifting equipment is likely to expand, providing a robust solution for elevating productivity while minimizing risks associated with manual labor.